In the field of semiconductor manufacturing, the material storage environment directly affects the yield rate of electronic components and product reliability. Against this backdrop, Huibo Robot Group has independently developed an intelligent nitrogen chamber system, which has attracted significant industry attention by providing full-life-cycle storage solutions for semiconductor materials through multiple innovative technical breakthroughs.

The intelligent nitrogen chamber system ensures a stable storage environment for semiconductor materials. As a chemically stable inert gas, nitrogen avoids oxidation reactions or electrostatic interference during material storage, ensuring stable material performance, extending service life, and laying a solid foundation for semiconductor manufacturing.

The intelligent nitrogen chamber system uses concentration regulation technology to precisely control the nitrogen concentration inside the chamber above 95%, allowing semiconductor materials to "safely rest" in an almost pure nitrogen environment. This significantly reduces oxidation risks and provides strong guarantees for material preservation.

Equipped with an environmental monitoring and control system, the nitrogen chamber continuously monitors key environmental parameters such as temperature and humidity 24/7. Once the system detects even minor deviations in data, it swiftly activates an automatic adjustment mechanism to ensure the chamber environment remains at the precisely set ideal state, creating the most suitable storage conditions for semiconductor materials.

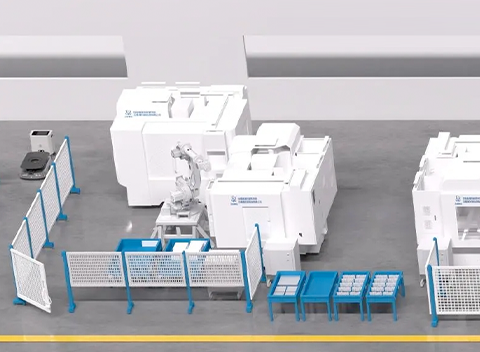

By integrating industrial six-axis robots, AGVs, and combining with the WMS intelligent warehouse management system, the chamber can automatically complete material warehousing, outbound, and inventory management operations. Through intelligent scheduling algorithms, it significantly enhances material flow efficiency, reduces manual intervention, minimizes operational errors, and improves the accuracy and efficiency of warehouse management.

Aiming at the strict environmental requirements of semiconductor manufacturing, the intelligent nitrogen chamber adopts anti-static coatings and high-standard cleanliness design. The chamber's environmental cleanliness reaches Class 1000 or above, effectively preventing static electricity accumulation and particle contamination, and providing a dust-free and static-free storage environment for semiconductor materials to ensure product quality and production reliability.

By optimizing the inflation strategy and arranging multiple inflation ports, the intelligent nitrogen chamber achieves rapid nitrogen filling, significantly shortening the nitrogen filling time, improving equipment utilization efficiency, and meeting the semiconductor industry's demand for fast storage.

Adopting a fully enclosed chamber design, strict sealing treatment is applied from the sealing panels to the induction doors, forming an all-round protection system. This effectively reduces nitrogen loss, maintains a stable chamber environment, and improves the economic efficiency of equipment operation.

To minimize the impact of the loading/unloading port on the chamber environment, the intelligent nitrogen chamber is equipped with a two-stage buffer chamber. This design effectively isolates external air, prevents temperature/humidity fluctuations and nitrogen concentration changes, and ensures the chamber environment remains in optimal condition.

Through automatic oxygen supplementation and pressure monitoring, the intelligent nitrogen chamber can maintain a micro-positive pressure state, further enhancing the purity of the chamber environment and providing a high-quality storage environment for semiconductor materials.

Fig:Huibo Robot Group's Intelligent Nitrogen Chamber

Huibo Robot Group's intelligent nitrogen chamber has been applied in well-known semiconductor enterprises such as Huatian Technology, achieving remarkable results in improving storage efficiency, ensuring material quality, and reducing operating costs. By seamlessly connecting with enterprises' ERP/MES systems, it realizes full-process automation and information management of production and warehousing links, strongly promoting enterprise digital and intelligent transformation.

With the vigorous development of the semiconductor industry, the requirements for storage technology continue to increase. Huibo Robot Group's intelligent nitrogen chamber effectively solves key technical challenges such as nitrogen concentration control, environmental monitoring and control, automated access and inventory management, anti-static and cleanliness design, providing strong support for industrial development.