Huibo Robot Group has successfully implemented an intelligent production line for PV cleaning robots at China Energy Engineering Group Nanjing Wire & Cable Company. This not only overcomes the above challenge but also injects strong momentum into new energy intelligent manufacturing under the national push for new energy development, opening a new chapter in industry growth!

Cleaning Challenges in PV Power StationsEfficient power generation in PV power stations relies on clean PV modules. Traditional manual cleaning is not only inefficient but also poses significant safety risks. Guided by the national "14th Five-Year Plan for Scientific and Technological Innovation in the Energy Sector", Huibo Robot Group has developed an intelligent production line for PV cleaning robots, achieving full-process intelligence from automated component production to finished product inspection and storage. This provides a brand-new solution for the efficient operation and maintenance (O&M) of PV power stations.

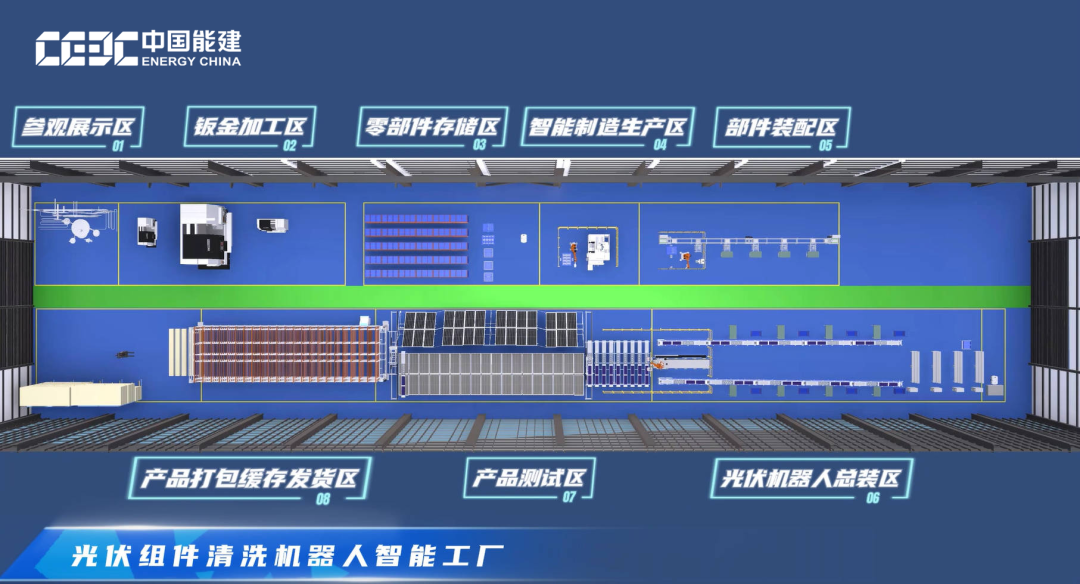

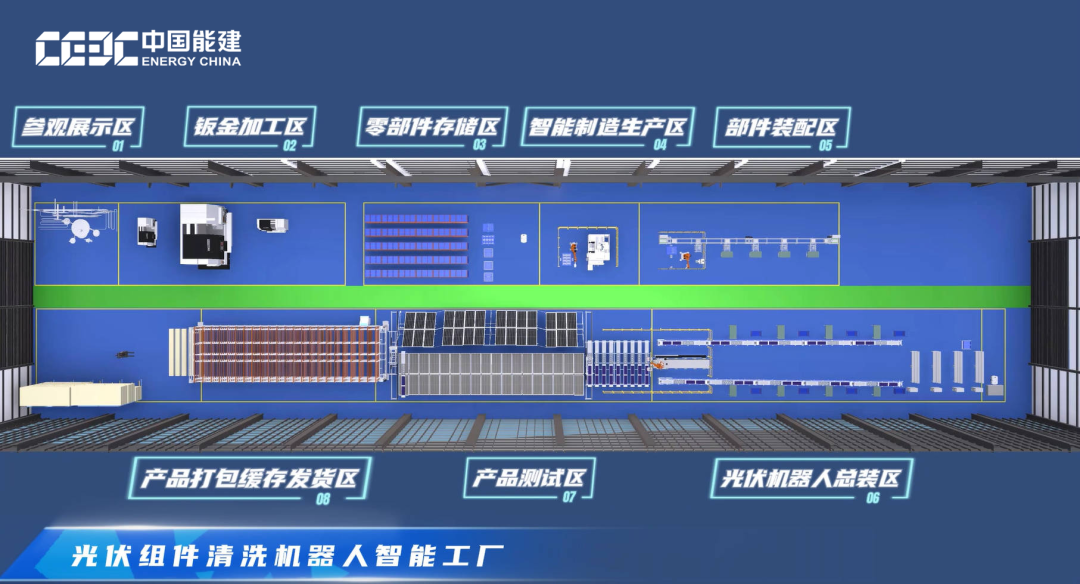

The intelligent production line for PV cleaning robots covers six zones: component storage, intelligent component manufacturing, component assembly, final assembly, whole-machine inspection), and packaging & shipping. Each workstation independently completes single-process tasks while cooperating with others, with logistics equipment connecting workstations to achieve seamless integration from raw material input to finished product output. This process not only improves production efficiency but also ensures precision and high efficiency in every link, providing a solid guarantee for PV power station cleaning O&M.

· In the early project implementation stage, Huibo communicated in detail with the client to design solutions based on client needs, combined with on-site production processes and workshop characteristics.

·Using digital twin technology, the plan was simulated and analyzed to confirm the feasibility of automated coordination for each workstation. The application of this technology not only enhanced the scientificity and rationality of the plan but also significantly shortened the project implementation cycle, ensuring smooth project progress.

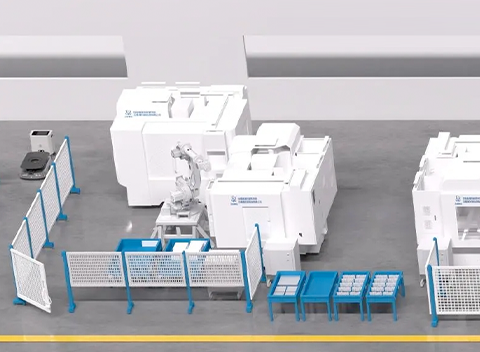

During implementation, Huibo organized professional engineers in mechanics, electrical, software, simulation, and project management to form a special team for centralized development, design, production, installation, and debugging. The project was completed and accepted within a short period, realizing automated production of PV cleaning robots. This achievement not only demonstrates Huibo's professional strength but also sets a benchmark for the industry, promoting the development of new energy intelligent manufacturing.

To further enhance the client's corporate image, Huibo designed and implemented a digital exhibition center, showcasing the advancedness and intelligence level of the production line as well as the enterprise's honorary qualifications. It has attracted the attention of many clients and partners, providing strong support for corporate brand building and market expansion.

Huibo fully utilizes AI vision technology to collect and analyze information on PV cleaning robot component production, component inspection, electrical component testing, and finished product function testing. This technology improves detection accuracy and efficiency, ensures each product meets high standards, reduces defect rates, enhances customer satisfaction, and provides quality assurance for efficient PV power station O&M.

The application of AGV technology realizes automated material handling and storage. The intelligent logistics system not only improves logistics efficiency but also reduces uncertainties and error risks in manual operations, lowering inventory costs and production waste, and providing efficient logistics support for PV power station cleaning O&M.

The application of robot handling technology achieves automated assembly of components and handling of finished products, improving production efficiency, reducing labor demand, and enhancing production safety and stability, providing strong production support for PV power station cleaning O&M.

The intelligent production line for PV cleaning robots realizes full-process automation from component production to finished product inspection, significantly shortening the production cycle and improving production efficiency. Compared with traditional production methods, production efficiency has increased by more than 50%, escorting the efficient O&M of PV power stations.

Through AI vision technology and precision inspection equipment, the production line conducts high-precision detection of components and finished products, ensuring each product meets high standards, improving product quality and consistency, and helping PV power stations operate stably.

Automated production and intelligent logistics systems reduce manual operations and labor costs. Meanwhile, efficient production processes and precise material management reduce inventory costs and production waste, with overall production costs reduced by more than 30%, empowering PV power stations to enhance economic benefits.

The high degree of automation in the intelligent production line reduces reliance on skilled workers, lowers uncertainties and error risks in manual operations, improves production safety and stability, and guarantees safe O&M of PV power stations.

Against the policy backdrop of the "Several Opinions on Promoting the Healthy Development of the Photovoltaic Industry" and "Made in China 2025", Huibo Robot Group's intelligent production line for PV cleaning robots provides a successful case and experience for the intelligent upgrading of the photovoltaic industry, driving technological progress and innovative development across the sector.

Under the guidance of the "double carbon" strategic goals, Huibo Robot Group will adhere to technological innovation, continuously inject strong momentum into the sustainable and healthy development of the new energy industry, and infuse the economy with new momentum for green development.