The frequency of traditional manual cleaning far lags behind the accumulation rate of pollutants. Digital intelligence serves as a key booster for building future industrial competitiveness. From April 15th to 16th, at the 137th Canton Fair, the intelligent cleaning solution for photovoltaic panels launched by Huibo Robot Group attracted extensive attention.

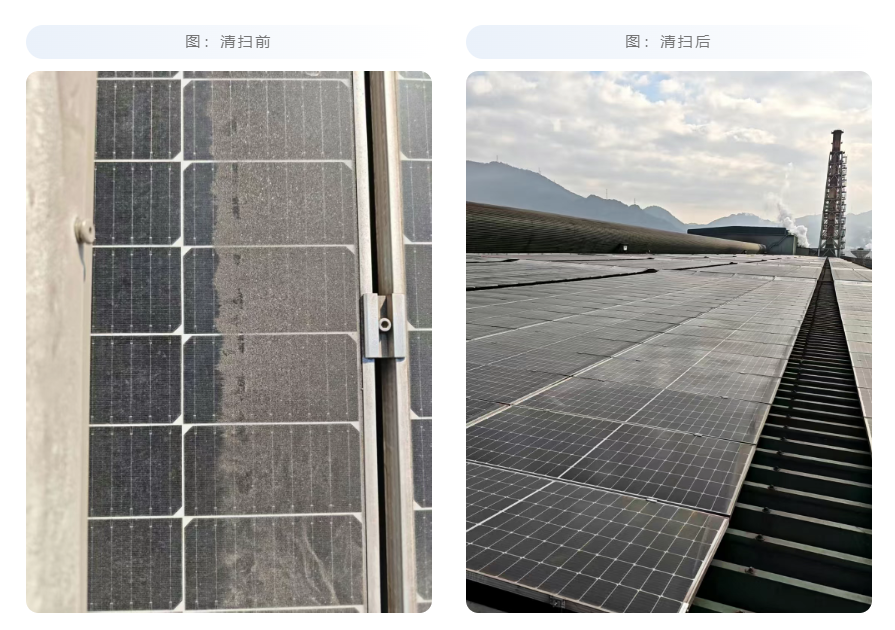

Driven by the "double carbon" goals, heavy industrial sectors such as thermal power and steel are accelerating the construction of rooftop photovoltaic power stations in factories. However, the industry challenge of severe pollutants like bird droppings and iron filings causing up to 30% power generation loss has consistently constrained the economic benefits of power stations.

Facing this dilemma, Huibo Robot Group has innovatively introduced an intelligent cleaning solution for photovoltaic panels. By applying its self-developed dedicated operating system for intelligent industrial mobile robots, the solution breaks through the predicament of traditional manual cleaning with an all-weather autonomous operation mode, opening up a new path for the operation and maintenance of photovoltaic power stations in high-pollution scenarios. The annual cleaning frequency of manual methods is only 4-12 times, and the cleanliness after a single cleaning can only be maintained for 5-7 days, resulting in photovoltaic power stations being in a power generation decay state for about 1/3 of the year, which significantly undermines economic benefits.

Meanwhile, the high risk of working at heights has made safety hazards in cleaning work ever-present. For example, a steel plant paid over one million yuan in insurance compensation for a cleaning accident in 2024, imposing a heavy burden of hidden costs on the enterprise.

During manual cleaning, missed cleaning issues frequently occur, with a missed cleaning rate exceeding 15%. This leads to significant dust accumulation at the edges of PV modules, forming a "black edge effect" that accelerates cell aging and severely impacts service life and power generation efficiency.

Additionally, industry surveys show that 75% of enterprises report cleaning personnel lack professional training. Due to the absence of necessary expertise and skills, non-standard operations by cleaners frequently trigger secondary failures such as hidden cracks and PID (Potential Induced Degradation) effects, further escalating O&M risks and costs for power stations.