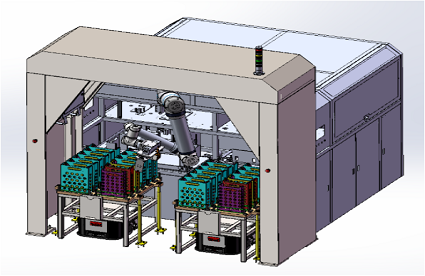

To assist the client in achieving intelligent upgrading of production processes, we have meticulously developed a solution for automatic material handling between the softening line and tinning line, as well as automatic loading/unloading for the tinning line. By deeply integrating AGV (Automated Guided Vehicle) automatic handling technology and robot automatic loading/unloading technology, a highly automated and intelligent "dark unmanned workshop" has been successfully constructed. On this basis, through the advanced AGV scheduling system and central control system, precise vehicle scheduling, efficient information management, and full-process traceability are realized, significantly improving production efficiency, product quality, and production stability, and opening a new era of intelligent manufacturing for the client.

Semiconductor frame sheet magazines

Through the implementation of automated transformation, the efficiency of material handling has been significantly improved, the dependence on manual operations has been greatly reduced, and the operation error rate has been effectively decreased, thus achieving the goal of reducing staff and increasing efficiency, and promoting the intelligent upgrading and high-quality development of the enterprise's production operations.

(1) Automatic Handling and Loading/Unloading: Realizes automated operations for material handling and loading/unloading, reduces manual intervention, effectively lowers employee labor intensity, and significantly improves work efficiency, helping enterprises optimize human resource allocation.

(2) Precise Distribution and Production Collaboration: The system dispatches orders in advance according to the production rhythm, and the distribution cycle precisely matches production needs, ensuring the continuity and stability of the production process and avoiding production interruptions caused by untimely material supply.

(3) Full-process Informatization and Traceability: Achieves full-process information recording, greatly improves the degree of automation, ensures the accuracy and traceability of production data, and provides strong support for the enterprise's refined management and quality control.

(4) Elimination of Human Errors: Completely solves the problems of missing scanning and incorrect scanning that may occur in the manual PDA scanning process, avoids production delays and quality risks caused by data anomalies, and further improves the standardization and reliability of production management.