I. Project Background

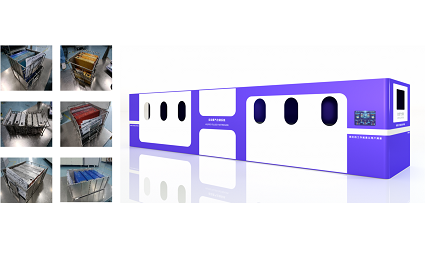

A smart three-dimensional storage system was developed for the client to store semiconductor materials (with specific requirements for oxygen concentration, temperature, and humidity). The system is equipped with industrial robots, a warehousing system, WMS, and other equipment, enabling automatic loading/unloading of materials from trolleys, automatic warehousing, and extended docking with AGVs for workshop distribution, significantly improving storage inbound/outbound efficiency.

Customized semiconductor carriers

Equipped with a WMS location system, the automatic allocation of storage locations greatly improves location utilization rate and significantly enhances inbound/outbound efficiency.

(1) Higher efficiency in automatic storage and inbound/outbound operations: By integrating high-speed stacker cranes and six-axis collaborative robots with the WMS intelligent warehousing management system, fully unmanned operations for semiconductor material boxes are realized. The system supports precise grabbing and shelf positioning of material boxes within 15 seconds, drastically improving inbound/outbound efficiency.

(2) Three-dimensional storage for more efficient space utilization: Multi-layer high-density shelves are configured to be compatible with various material box sizes. The automatic allocation of storage locations through the location management system significantly improves the utilization rate of original storage space.

(3) Real-time monitoring of nitrogen concentration, temperature, and humidity for safer storage: Distributed high-precision sensors are deployed to regulate the storage environment: nitrogen concentration is stably controlled within the range of 90%, humidity deviation ≤ ±0.5%RH, complying with EHS certification standards.

(4) Real-time display of storage status for convenient management: Based on the intelligent warehouse location management system, dynamic data of all storage locations can be tracked in real time and deeply interconnected with the upper-level system. It supports batch cycle traceability of materials, intelligent validity period early warning, and inventory heat map analysis, enabling managers to make remote decisions on most warehousing businesses through mobile terminals.