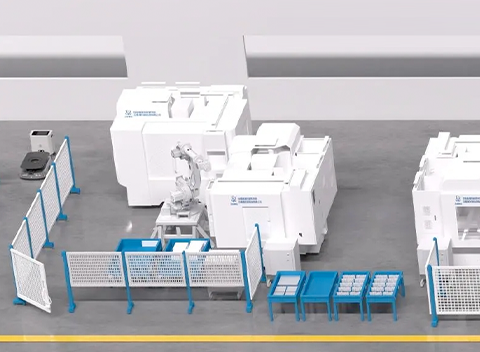

To address the project's challenges, Huibo Robot Group relies on its self-developed intelligent PV module cleaning robots and dedicated implementation operating system for intelligent industrial mobile robots to provide customized solutions, bidding farewell to traditional manual cleaning and unlocking the code for improving power generation in agrivoltaic PV power stations!

Insurmountable Height Challenges

PV modules are nearly 3 meters above the ground. Manual cleaning not only requires lifting tools but also water trucks, incurring high labor and material costs.

Severe Bottleneck in Cleaning Frequency

Constrained by high costs, cleaning can only be carried out 2-4 times a year. Accumulated dirt significantly reduces the light transmittance of PV modules.

Hidden Damage Risks

Non-standard manual operations easily cause hidden cracks and PID degradation in modules, falling into a vicious cycle of "the more they clean, the more damage they cause," worsening power station O&M.

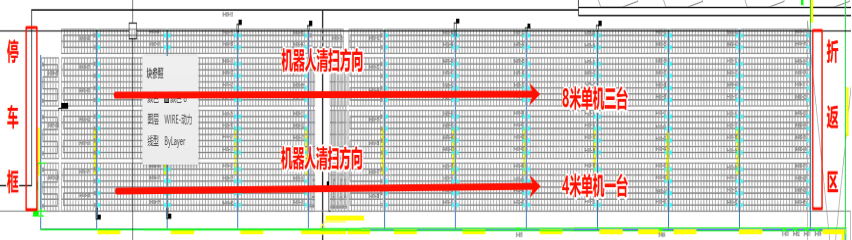

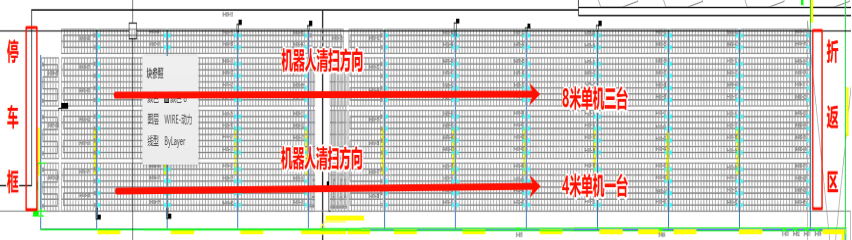

Based on basic information such as the client's installed capacity and power station pollution sources, Huibo's professional engineering team designs auxiliary components for the project, arranges the optimal number of robots, and provides the most cost-effective solution according to the module layout, bracket structure diagram, and on-site survey results.

(Robot configuration)

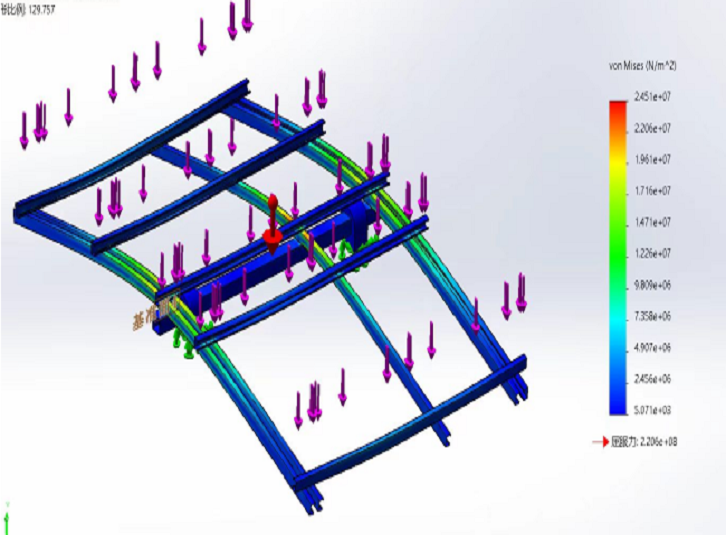

Meanwhile, professional simulation software is used for force analysis to ensure the plan is solid and reliable.

(Auxiliary material simulation analysis)

High-frequency Maintenance Mode: Increases effective cleaning frequency to 2-3 times a week, maintaining continuous light transmittance of modules.

IV Curve Diagnosis Function: Monitors module output characteristics in real time, pre-warns string anomalies, and extends the power station's lifecycle.

Intelligent Production Base Layout: Coordinated by three major bases in Guangdong, Hebei, and Inner Mongolia, intelligent cleaning robot production bases with an annual output of 100,000 units have been built in Zhangjiakou, Hohhot, etc., equipped with fully automated production lines to ensure high consistency and reliability of each product.

Self-developed Core Technology Empowerment: Equipped with self-developed gear motors, optimized transmission mechanism design, improved robot reliability, and further extended service life.

Professional Construction Management: Implements unified standardized management, ensures delivery teams work with certificates, strictly enforces construction specifications, and establishes a "one-machine-one-file" full-cycle traceability mechanism, keeping clients worry-free throughout.

Huibo Robot has delivered an outstanding answer for the intelligent O&M management of this power station. After nearly 9 months of continuous and stable operation, the power station has achieved a 5%-10% monthly average power generation growth, with remarkable results.

The high-frequency cleaning mode of intelligent cleaning robots keeps PV modules in optimal working condition at all times. Meanwhile, flexible brush bristles combined with intelligent obstacle-crossing technology provide safe cleaning 保障 (assurance) for modules, significantly extending their service life.

"Previously, we worried about module cleaning every month; now robots 'go to work' by themselves, and we just need to check the data. Stable power generation truly achieves cost reduction and efficiency improvement," said a relevant person in charge of the power station. The intelligent cleaning solution has truly realized unmanned and intelligent high-efficiency O&M.

The successful practice of this project provides a replicable intelligent O&M model for agrivoltaic centralized power stations. By increasing the cleaning frequency from quarterly to daily, PV modules always maintain optimal working conditions, truly achieving the cost optimization goal of "trading technology for power generation."

In the wave of energy transition, Huibo Robot will continue to deepen technological innovation, continuously iterate and optimize product performance, join hands with more partners to help enhance the full-life-cycle value of PV power stations, and contribute more to the national energy structure transformation!