To address the challenges of traditional train carriage residual cleaning, Huibo Robot Group has developed the Intelligent Cleaning Robot System for Open-top Train Carriage Residual Materials, breaking through key core technologies such as negative pressure cleaning and pipeline anti-blocking. This system realizes integrated cleaning, collection, and recycling of carriage residuals, filling the industry gap of robot.

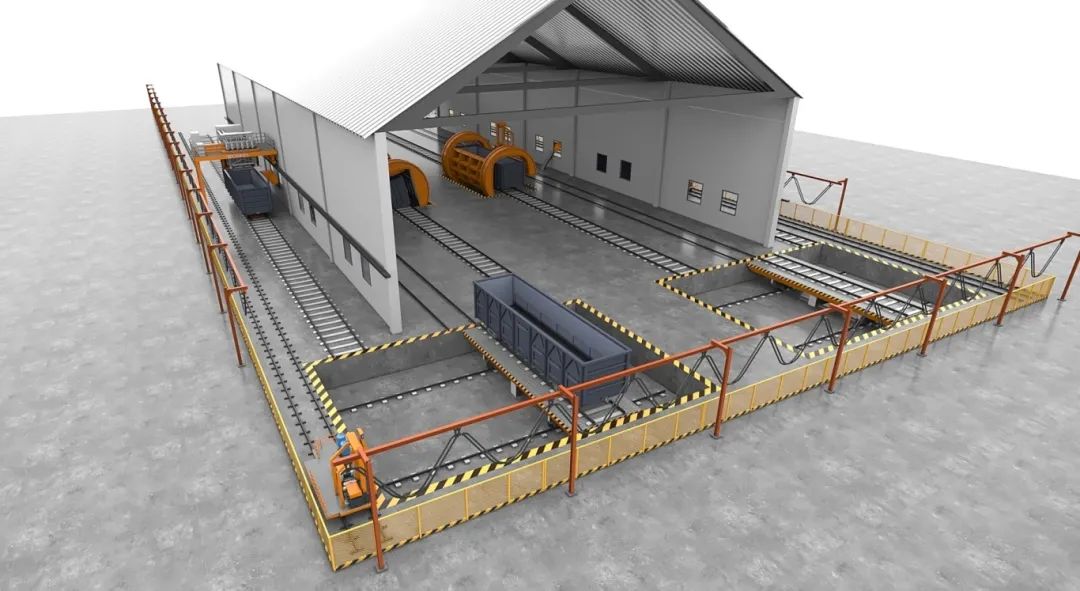

Huibo's intelligent train carriage cleaning robot (hereinafter referred to as the "car cleaning robot") consists of multiple key components, including an intelligent gantry cart, mobile trolley, lifting device, negative pressure suction system, adaptive sweeper, hydraulic system, control system, and monitoring system. It enables intelligent cleaning of residual materials such as wet sticky coal and slightly compacted coal in carriages after unloading by car dumper, screw unloader, or overhead crane.

· Intelligent Gantry Cart stands stably on both sides of the train track, providing a stable support and mobile foundation for the robot, allowing it to move flexibly along the track and follow the position of train carriages.

· Mobile Trolley moves left and right on the gantry's crossbeam, precisely delivering the cleaning device to various positions in the carriage.

· Lifting Device adjusts the position of the cleaning device according to the carriage height, ensuring comprehensive coverage of every corner—including the bottom, walls, and edges—of the carriage.

· Negative Pressure Suction System features strong suction, quickly drawing up dust and residual materials into the collection device during cleaning to prevent dust overflow and solve the problem of dust pollution at its source.

· Adaptive Sweeper consists of multiple adjustable cleaning brushes that automatically adjust angles and force based on the internal shape of the carriage and residual material conditions, achieving efficient and thorough cleaning.

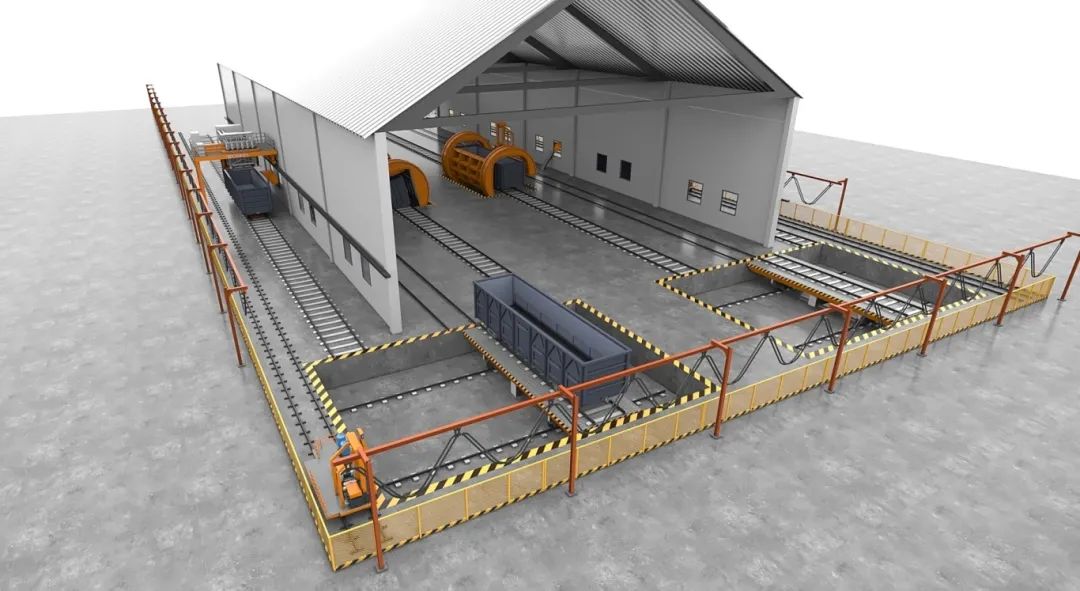

The car cleaning robot excels in safety, building a solid defense line for workers. During traditional manual cleaning, staff faced significant risks when entering carriages. In contrast, the robot requires no human entry, allowing operations to be controlled via an intelligent control system outside the carriage.

· Away from Hazardous Environments: Workers operate the robot from a safe zone using monitoring screens and control handles, significantly reducing the probability of safety accidents.

· Safety Interlock Mechanism: The robot establishes a safety interlock with the car dumper to avoid risks from cross operations. When the dumper is working, the robot stops automatically; it starts cleaning only after the dumper completes unloading and safety is confirmed, ensuring operational safety throughout.

With increasingly strict environmental requirements, the car cleaning robot sets a new benchmark for green cleaning in thermal power plants. Using strong negative pressure suction technology, it acts like a super vacuum cleaner, quickly absorbing residual materials and dust into the collection device. The cleaning air volume reaches 17,000m³/h, and it can absorb materials with a maximum diameter of 180mm.

· Fully Sealed Collection and Conveyance: During operation, the robot uses sealed pipes and collection devices to fully seal and convey absorbed materials and dust, preventing leakage and eliminating dust pollution at the source.

· Multi-stage Sedimentation Filtration Technology: Equipped with a patented multi-stage filtration system, it filters inhaled air layer by layer to ensure discharged gases meet strict environmental standards. After cleaning each carriage, the robot performs high-pressure gas backblowing to clean the filter element, maintaining optimal filtration efficiency for continuous environmental protection.

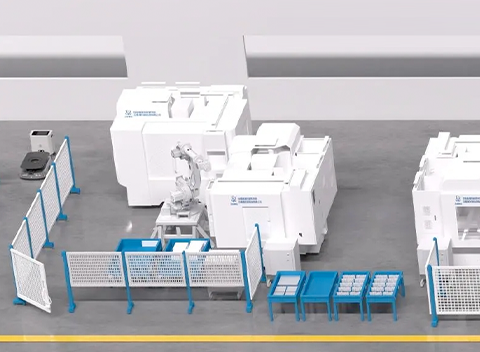

Huibo's intelligent train carriage cleaning robot brings a brand-new cleaning experience to thermal power plants through its excellent intelligent features .

The robot boasts strong adaptability, automatically adjusting to common carriage models such as C60, C62, C64, C70, C70E, C70EH, and C70E-A. It adjusts the width and height of the sweeper based on carriage dimensions and structural features. When encountering uneven carriages (e.g., dents, repairs, damage), the cleaning brushes maintain effective contact with the carriage, ensuring comprehensive and thorough cleaning while precisely staying in the middle to avoid blind spots.

In addition to adaptability, the robot is equipped with an advanced video monitoring system, allowing operators to view real-time cleaning conditions inside the carriage and conduct full-process monitoring. In case of incomplete cleaning or equipment failures, adjustments and repairs can be made promptly.

In terms of operation, the robot features a user-friendly human-machine interface, enabling operators to command the robot to complete cleaning tasks with one-click operations via control handles or computer interfaces in the control room, achieving true intelligent remote control.

The car cleaning robot demonstrates significant advantages in efficiency, standing in sharp contrast to traditional manual cleaning.

Traditional manual cleaning of one carriage takes 15-20 minutes, with time extending further under conditions of heavy residual materials, high viscosity, or poor weather. The robot completes the task in only 3-5 minutes, achieving severalfold efficiency improvement.

Moreover, the robot supports 24-hour continuous operation, eliminating concerns about labor shortages or work-time restrictions in thermal power plants. This ensures trains are promptly available for the next transport, improving train utilization and material turnover speed.

In practical applications, the robot's high efficiency avoids fines from railway departments due to prolonged train stays. Meanwhile, accelerated material turnover in thermal power plants enhances production efficiency, bringing considerable economic benefits.

Moving towards "green" and advancing towards "intelligence," Huibo's intelligent train carriage cleaning robot is applicable in thermal power plants, steel mills, coal preparation plants, metallurgy, ports, chemicals, and other fields. It solves industry pain points such as high-risk cleaning operations, harsh working environments, pollution, and labor shortages, injecting strong momentum into high-quality energy development through its safety, environmental protection, intelligence, and efficiency.

In the future, Huibo Robot Group will rely on domestically developed and controllable technologies to create typical application scenarios for industrial robots in the energy sector, promote the construction of intelligent manufacturing demonstration factories, and play an active role in transforming economic development patterns and unleashing economic potential.