I. Project Background

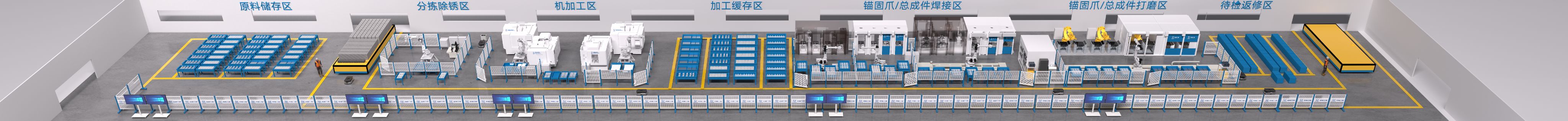

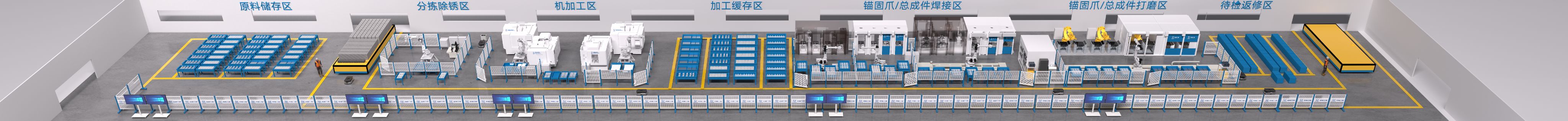

An all-automated production system for nuclear power plant embedded parts was realized for the client. Through the application of technologies such as laser derusting, robotic visual positioning for loading/unloading, robotic welding, robotic grinding, AGV transportation, WMS, and digital twin, automated operations for derusting, machining, assembly, welding, and grinding of embedded parts were achieved. Informatized management was implemented, significantly improving production efficiency, quality, and production stability.

Nuclear power plant embedded parts

The production line features high automation, flexibility, and intelligence, compatible with multi-product production. It solves the client's challenges of heavy manual labor dependency and high skill requirements for workers, improving production efficiency and capacity while ensuring reliable and stable quality.

(1) Process Integration & Robotic Operations: By researching and testing embedded part production processes, robotic technologies eliminated the need for skilled workers in machining, welding, and grinding. Closed-loop automated welding and grinding operations were achieved, reducing environmental impact.

(2) Machine Vision Recognition & Positioning: Machine vision identifies and positions products of different specifications, guiding robots to complete automatic grasping and high-precision loading/unloading.

(3) Automatic Logistics Distribution: Through AGV cluster scheduling, optimized flexible material distribution is realized to meet distribution requirements for different products and processes.

(4) Digital Management: WMS and digital twin systems enable equipment data collection and control, assisting managers in scheduling, operation, and maintenance to improve system capacity and efficiency.