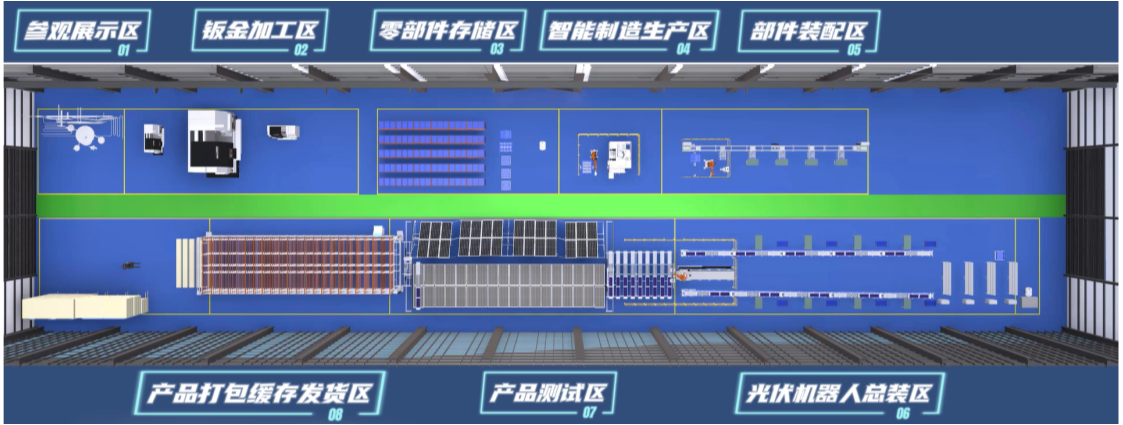

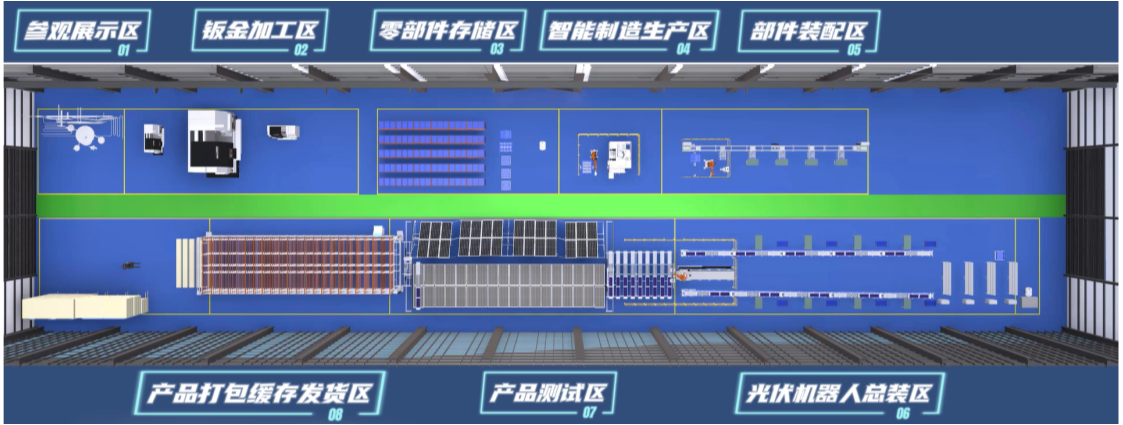

I. Project Background

The intelligent production of photovoltaic cleaning robots is achieved through the logistics system, warehousing system, automated processing system, and WMS software system. The project includes functions such as automated processing of components, robotic automated assembly of components, human-robot collaborative assembly of components, final assembly of photovoltaic cleaning robots, automated conveying and transfer, and automated performance testing and analysis.

Photovoltaic cleaning robots

The production line significantly improves the production efficiency and product quality of photovoltaic cleaning robots, with high flexibility and intelligence. It can produce multiple specifications of photovoltaic cleaning robots and enhance production capacity.

(1) Robotic Automated Operations: 3D vision-guided robotic picking is used for automated machining of photovoltaic cleaning robot parts. The assembly process of photovoltaic cleaning robots is analyzed, and robots 配合 (collaborate with) specialized assembly machines for automated assembly.

(2) Human-Robot Collaborative Operations: The assembly process of photovoltaic cleaning robots combines manual and robotic operations. Manual assembly of components is performed, and automated equipment transports between processes. For complete machine electrical assembly and final assembly, automated conveying equipment is used for transportation, and rotating equipment adjusts angles to dock with inspection and buffer processes.

(3) High Flexibility: The production line features high flexibility, compatible with the production, inspection, and storage of multiple photovoltaic cleaning robot specifications. The inspection process detects robot performance, motor speed, battery parameters, etc., to ensure production quality.

(4) Logistics and Storage System: AGVs transport materials between the parts storage warehouse and each process. Buffer stations and storage locations are configured for in-process buffering, enhancing production flow.