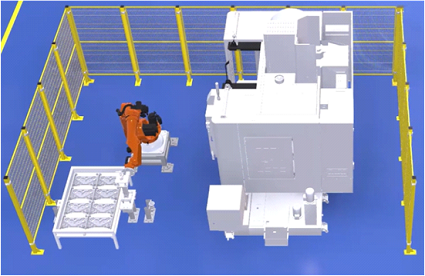

An automated production workstation was constructed for the client. Through the application of robotics, AGVs, and vision technology, automated processing, production, and transportation of parts were realized. AGVs automatically deliver materials to the workstation, robots automatically transport them to CNC machines for processing, and after processing, parts are visually inspected, placed in material carts, and transported by AGVs to the next process.

Automotive parts

With the continuous increase in labor costs, there is a need to change the existing production model. This system is compatible with manual logistics and loading/unloading operations, while featuring high flexibility and automatic inspection functions, reducing labor costs while improving efficiency and product quality.

(1) Robotic Automated Handling: Visual guidance is used for automated loading/unloading of parts, and flexible fixtures are adopted to be compatible with multiple product models.

(2) AGV Logistics Technology: AGVs handle logistics, connecting with upstream and downstream processes and seamlessly cooperating with robotic workstations to reduce manual handling and improve production efficiency.

(3) Visual Inspection Technology: Processed products undergo visual inspection to ensure product quality and enhance product consistency.