I. Project Background

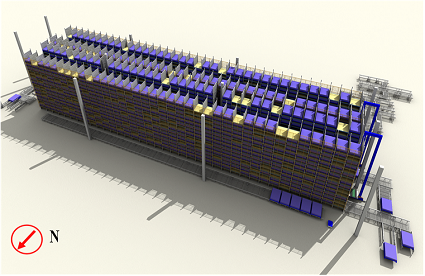

An intelligent three-dimensional warehousing system for automotive batteries was constructed for the client. Through the application of equipment technologies such as double-lane stacker crane clusters, high-speed conveying lines, AGV flexible handling systems, and process-embedded WMS, full-link automated operations were realized for processes including inbound temporary storage-discharge period process control-outbound sorting, achieving informatized management and improving production efficiency, quality, and production stability.

Automotive batteries

The project constructs a high-density three-dimensional warehousing system through double-lane stacker crane clusters + intelligent scheduling algorithms, achieving core breakthroughs in space utilization and inbound/outbound efficiency.

Innovatively integrates temperature & humidity control + triple fire protection systems to ensure battery storage safety.

Deeply integrates with WMS to improve inventory turnover and achieve precise full-life cycle traceability.

(1) Intelligent Warehousing Space Reconstruction: Based on a three-dimensional warehousing system with double-lane stacker crane clusters, through WMS dynamic location allocation algorithms + RFID full-pallet binding technology, 3D digital modeling and real-time status tracking of 2,034 storage locations are achieved. Combined with the conveying line automatic deviation correction device, inbound/outbound efficiency is increased by 40%, and operation accuracy reaches 99.97%.

(2) Multi-modal Fire Sensing System: Constructs a rack-level intrinsic safety protection system, deploys laser smoke sensors + distributed temperature sensor arrays, combines with a fireproof board isolation structure with a 2-hour fire resistance limit, and develops a fire classification response mechanism. Through hardwired interlocking between the fire control panel and stacker cranes/AGVs, fire source isolation and equipment emergency stop are completed within 30 seconds.

(3) Mobile Equipment Active Protection System: Customizes high-temperature resistant ceramic armor + high-pressure fine water mist fire extinguishing modules for stacker cranes, embeds temperature sensors in key parts of lifting mechanisms and traveling wheel sets, and automatically triggers in-cabin fire extinguishing agent spraying in case of abnormal temperature rise.