I. Project Background

Foshan Disena Technology Co., Ltd., a Sino-US joint venture founded in 2000, mainly produces ergonomic products (electric/pneumatic lifting desks, children's study desks, e-sports desks), office supplies, household storage and decorative items, educational supplies, and provides overall office space solutions.

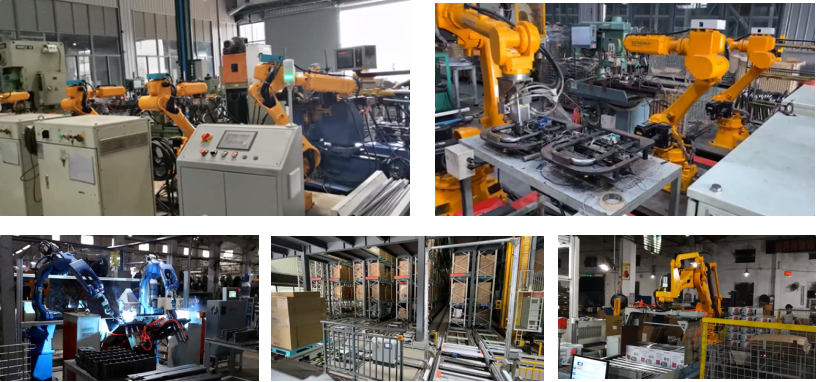

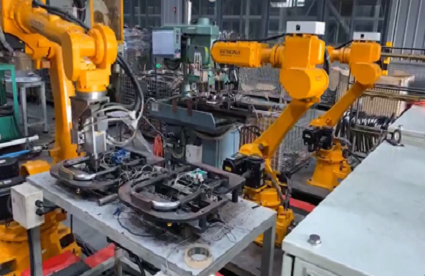

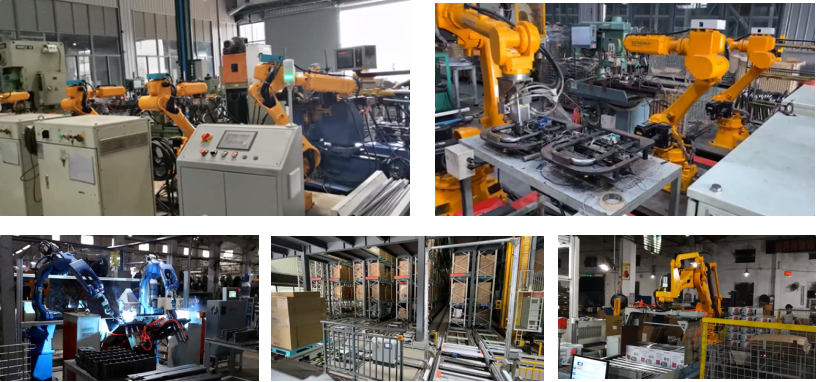

Our company has provided Disena with robotic automated loading/unloading production lines, robotic collaborative welding units, automatic packaging and palletizing systems, and three-dimensional warehousing systems.

Pipe fittings, finished product pallets

(1) Production efficiency increased from 600 pieces/day to 2,500 pieces/day;

(2) Number of workers reduced from 1,000 to 700, output value increased from 220 million to 500 million yuan, and per capita output value increased from 220,000 to 710,000 yuan/person.

(1) Robots replace manual labor, reducing labor costs and improving production efficiency;

(2) Intelligent storage enables automatic entry/exit and automatic location recording, ensuring accuracy and efficiency.