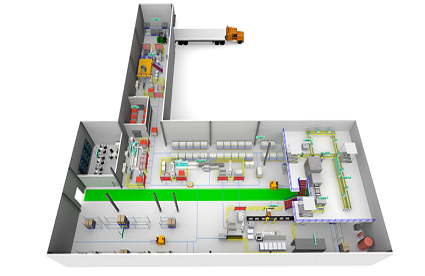

Project implementation location:Dongguan City, Guangdong Province

Highly Automated Processes: Six-axis industrial robots are adopted to automate complex operations such as automatic loading/unloading of clay bodies and kiln cars, improving production efficiency and reducing manual intervention.

Advanced Visual Inspection Technology: Visual inspection modules are used for automatic detection of membrane sheets, accurately identifying issues like deformation, cracks, and defects to effectively enhance product quality control and reduce defect rates.

Efficient Automatic Distribution System: Automated logistics equipment such as latent AGVs and forklift AGVs enable automatic distribution of clay body boxes, felt boards, and finished products across production links, optimizing logistics processes and improving efficiency.

Comprehensive Digital Management: An information system is introduced to achieve full digital management of production processes. Data from raw material feeding to finished product warehousing can be traced in real time, facilitating production monitoring, quality control, and decision optimization.

Intelligent Warehousing & Logistics: The automatic finished product warehousing system, combined with automated warehousing equipment, realizes automatic storage and management of finished products, improving warehouse space utilization and cargo handling efficiency.

Enhanced Production Stability: The application of automated equipment and information systems reduces human influence on production, making processes more stable and reliable and lowering production accident risks.

Reduced Labor Intensity & Costs: The automated production system replaces numerous tedious and high-intensity manual operations, alleviating worker labor intensity and reducing enterprise labor cost input.

Strengthened Market Competitiveness: By improving production efficiency, product quality, and stability, the enterprise can better meet market demands, enhance product competitiveness, and lay a solid foundation for sustainable development.